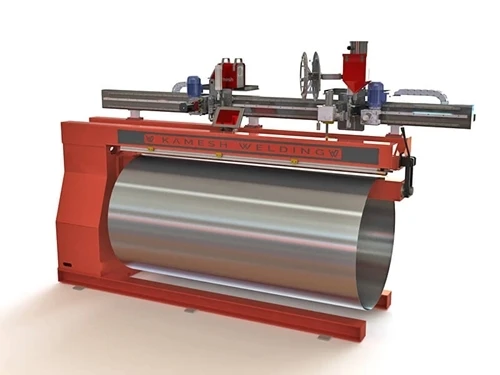

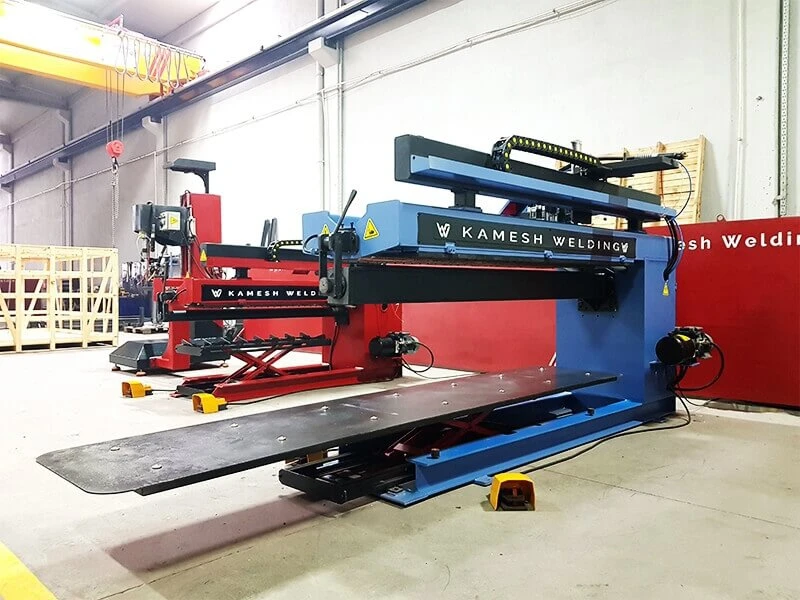

Longitudinal seam welding system is designed for welding longitudinal seams of cylindrical, conical, rectangular, circular metal containers and round workpieces, used in the petroleum industry, wind power generation line, pipe production line industries. Length welding of materials such as solar energy boilers, natural gas chimneys, cooling and fuel tanks, thermosiphon, lpg tubes are easily made with a longitudinal seam welding machine.

Automatic longitudinal seam welding machine works in harmony with gas welding, submerged arc welding, argon arc welding and other welding methods.

| Technical Details |

KWBKM-1000 |

KWBKM-1500 |

KWBKM-2000 |

KWBKM-3000 |

| Work Pieces Diameter (Min.Max/MM) |

100-650 |

150-650 |

250-800 |

350-800 |

| Work pieces Lenght (MM) |

1000 |

1500 |

2000 |

3000 |

| Metarial Tichkness (MM) |

0,6-10 |

0,6-10 |

0,6-10 |

1-10 |

| Pressing Power (BAR) |

8 |

8 |

8 |

8 |

| Input Power |

380V-50 Hz |

380V-50 Hz |

380V-50 Hz |

380V-50 Hz |

| Welding Speed (MM/Dak) |

0-2000 |

0-2000 |

0-2000 |

0-2000 |

| free Speed (MM/Dak) |

3000 |

3000 |

3000 |

3000 |

| Dimension (MM) |

2100x2000x1200 |

2700x2100x1200 |

3250x2500x1200 |

4250x2500x1200 |

| Color |

Red - Black |

Red - Black |

Red - Black |

Red - Black |

| Welding Method |

Tig /Migmag/Saw |

Tig /Migmag/Saw |

Tig /Migmag/Saw |

Tig /Migmag/Saw |

| Weight KG |

1200 |

1600 |

2350 |

3000 |

Kamesh Welding manufactures solar energy boilers longitudinal seam welding machine, natural gas chimneys seam welding machine, cooling and fuel tanks longitudinal welding system, natural gas chimneys longitudinal seam mig welding machine, thermosiphon longitudinal seam welding machine, lpg tubes longitudinal seam welder.